Soil Stabilisation

Our team have been at the forefront of soil stabilisation for decades.

No-one matches DGS on experience in stabilising even the most problematic soil types.

Our team are experts in soil stabilisation. We use stabilisation both as a stand-alone technique and as part of our patented hybrid solutions.

Stabilisation which works by improving in-situ earth into an engineered material, which in turn form part of our warrantable, environmental foundations. As a stand-alone solution we treat existing on site materials with stabilisation before capping. Clients benefit from drastically reduced capping import and associated environmental and financial costs.

Our patented hybrid solutions combine both stabilisation and dynamic compaction techniques to drastically improve the engineering properties of existing ground materials. By virtue of our patent, we are the only provider of this hybrid approach. The hybrid solution firstly allows for much greater warrantable bearing values than stand-alone solutions. The hybrid approach also allows for faster programme times and in many cases lower costs.

We are specialists at tackling soils that are ordinarily problematic to stabilisation. In particular we are experts in tackling soils with high sulphate levels. Where necessary, we create bespoke blends of stabilisation agents that enable treatment of otherwise ‘stabilisation-prohibitive’ soils. This capacity allows us to create pile free solutions in all but the most challenging of terrains.

We operate both Wirtgen andStehr stabilisation units according to project requirements. Our equipment mix creates a bespoke approach delivering both the necessary speed and precision of modern development.

Please contact us if you would like to discuss either the details of our hybrid solution or stabilisation techniques more generally. We are happy to consult with engineers at even the earliest stages of project development.

Our Equipment

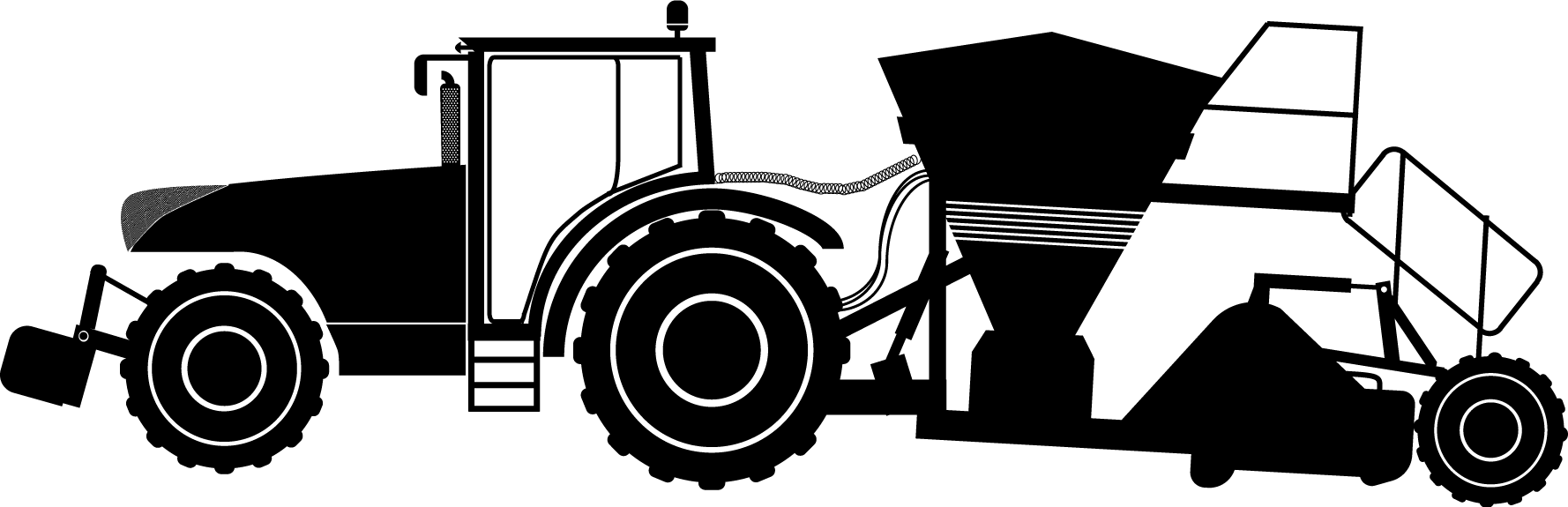

Fendt 936 Vario

A 366HP engine powers the hi-tech drive control ensuring reliable grip at a consistent speed. The unit’s variotronic software helps automate the process removing operator variance.

Stehr SBF 24-6 Dust Free

The largest integrated, tractor-towed integrated mixer on the market today. The unit completes stabilisation tasks rapidly, reliably and without the need for additional water units.

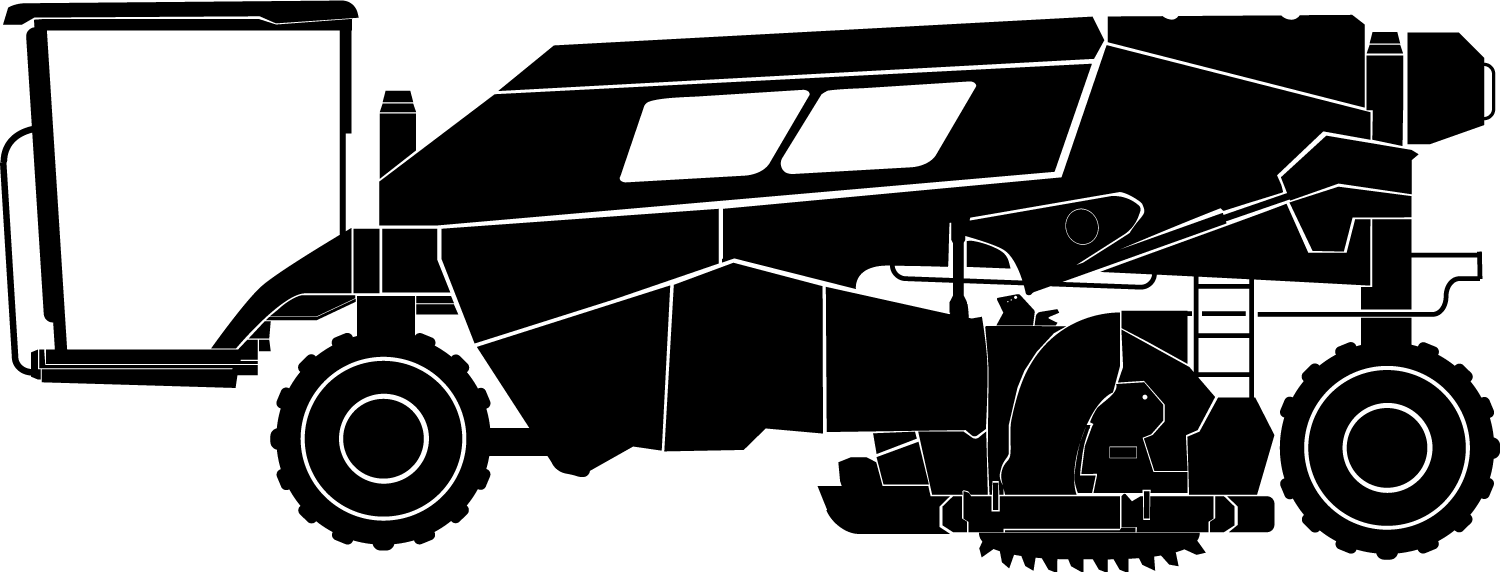

Wirtgen WR250

The largest Wirtgen unit operating on today’s market, the WR250 is the successor to the 2500 Wirtgen model. Offering superior stabilising capacity the WR250 undertakes our larger stabilising projects.